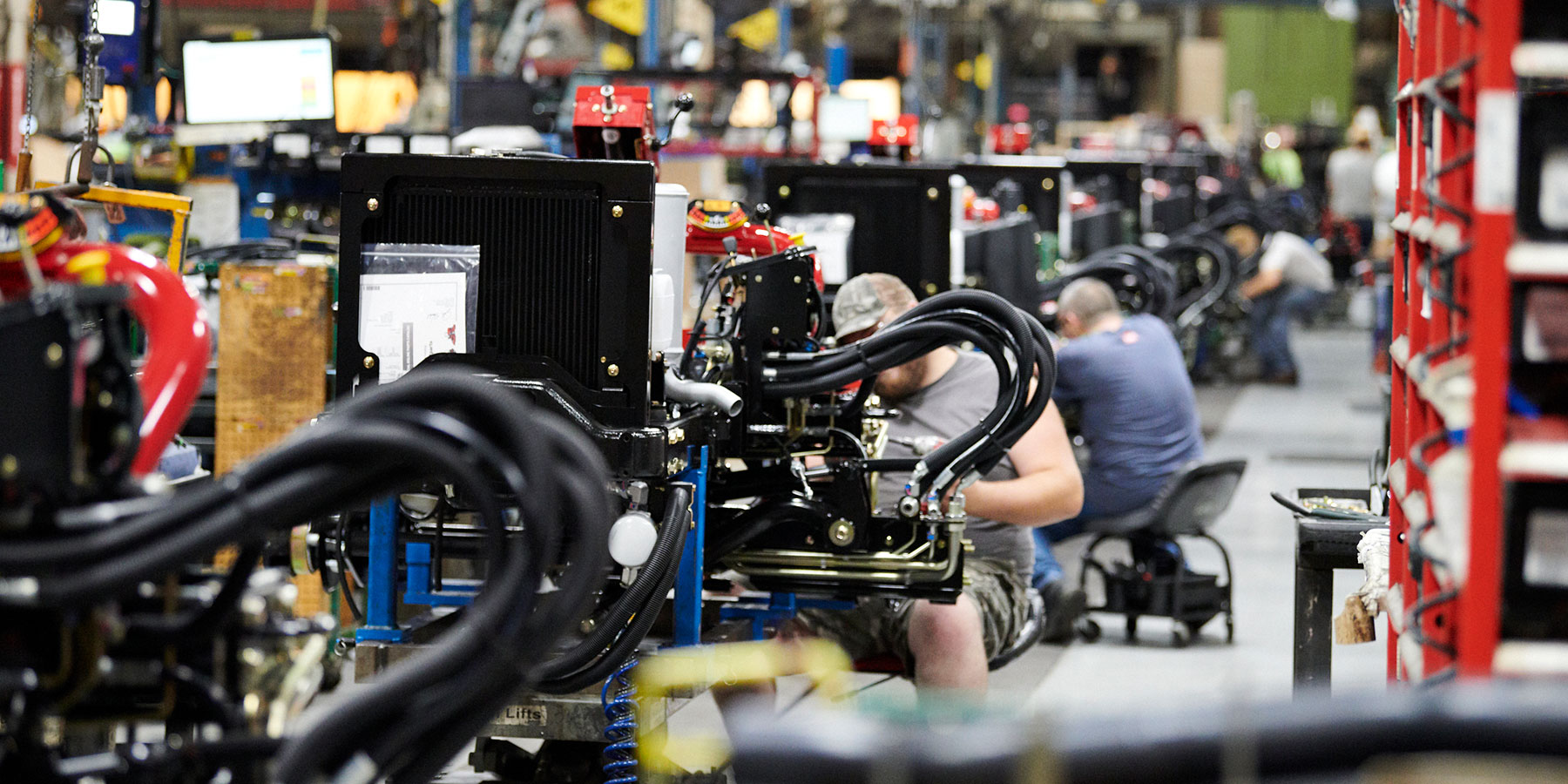

Process

Our process facilitates the delivery of the top-quality products our customers and partners have come to expect for over a century. Through continuous improvement, we execute operational excellence and resource efficiency in our integrated supply chain, reinforced by our enduring commitment to quality.

Materials Sourcing

We carefully manage the sourcing and use of components necessary for production to promote responsible sourcing practices. To manage our impact and resources in an ethical and responsible manner, sourcing agreements and supply chain management policies and procedures target the removal of restricted substances in products. Learn more.

Monitoring, Targeting and Reporting

Our Monitoring, Targeting and Reporting (MTR) program provides us with data tracking capabilities and monitoring of performance indicators to reflect data performance trends and provide insights into operational improvement areas. As a result, we better understand our consumption patterns, allowing us to communicate implications with our sustainability teams. Monitoring and reporting these results help identify cost savings from process and equipment efficiency improvements. Learn more.

Operational Energy Use and GHG Emissions

We have implemented various systems to help monitor our performance and adjust operations as we work towards our goal to reduce absolute Scope 1 and Scope 2 greenhouse gas (GHG) emissions by at least 15% by fiscal 2025 as compared to fiscal year 2019.We seek to increase the share of energy coming from renewable sources, continue transitioning our facilities to LED lighting, and expand our integration of energy-efficient process equipment. Learn more.

Operational Water Use and Conservation

As a global company, we recognize the opportunity to support water-reduction efforts through our processes and product solutions. We leverage recycled water from water reclamation and treatment plants, where possible, to limit the intake of fresh water. We use our data management system to help us better understand water risks and opportunities to improve our water use efficiency and to identify areas to further develop water best practices in our facilities. Learn more.

Operational Waste

Through our Monitoring, Targeting and Reporting system, we understand how and where we generate waste in our manufacturing processes. We can leverage this knowledge and our lean enterprise approach to minimize overall waste across our operations. This includes applying more circular processes to reduce the amount of waste sent to landfills and promoting responsible sourcing and resource usage. In 2022, our facilities continued to recycle resin moldings and packaging scraps (steel, aluminum, plastics, cardboard and paper) and compost food waste, where possible. Learn more.

Sustainable Facilities

To complement our management systems, we implement sustainable design elements for existing and new buildings. For example, our manufacturing facility in Tomah, Wisconsin, received the Focus on Energy® 2022 Energy Efficiency Excellence Award for the adoption of sustainable design and process upgrades. Across our facilities, we focus on site specific green building features where applicable. Learn more.